Carbon Black Powder Automatic Dosing System

- 01

- 02

- 03

- 04

- 05

- 06

- 07

- 08

- 09

- 10

- 11

- 12

Set up 11 years, our company own the factory. and experienced Focus on high quality and good price

Since receiving orders, our production has undergone multiple quality checks

Lead time is about 15-45 days after receiving your deposit Repeat order will be shorter

Raw materials are safe and healthy, don't add the harmful material

Years Of Experience

Hardware Equipment

Floor Space(m²)

Daily Delivery Volume

01

01

02

02

03

03

04

04

05

05

Qingdao Augu Automation Equipment Co., Ltd., established in 2013, is a remarkable enterprise in the tire machinery field. Guided by "aspiration, innovation, and enterprise", it focuses on enhancing automation for small and medium - sized tire factories. Its flagship product, the tire mileage testing machine, features high - precision mileage simulation, wide - range temperature control, and strong load - bearing capacity. With user - friendly operation, modular design, and a great cost - performance ratio, the product sells well both at home and abroad. The company will showcase its latest products at the Global RubberLatex & Tyre Expo in Thailand from March 12 - 14, 2025, Booth J19, aiming to offer comprehensive industry solutions.

View More

Augu Automation Equipment Co., Ltd.: tyre equipment manufacturing Year-End Review, Impressive Performance, Aiming for Greater Success in 2025

View More

Recently, Qingdao AUGU Automation Equipment Co., Ltd. had the honor of participating in the Lahore Industrial Exhibition in Pakistan, which is an important platform for showcasing innovation and building strong connections in the industrial field. The event brings together leading companies from various industries, and AUGU is excited to be a part of it, especially in a city as vibrant and historic as Lahore.

View More

Qingdao Augu Automation Equipment Co., Ltd. sincerely invites you to visit the Pakistan Industrial Exhibition

View More

As a major event in the industry, the Shanghai Rubber Exhibition has recently attracted global attention with its unique charm. On this platform that brings together rubber technology innovation and market trends, Qingdao Augu Automation Equipment Co., Ltd. stepped into this event with full enthusiasm and firm steps. As the exhibition entered the second day, the atmosphere on site became more and more enthusiastic. We not only felt the pulse of the booming industry, but also saw the unlimited possibilities of future cooperation.

View More

Tire capsule is used in the process of tire production to finalize the embryo, pressure, heat conduction, tire capsule is a barrel or orange shape of pure rubber products. The traditional production method of tire capsules is molding.

View More

In July and September 2024, Qingdao Augu Automation Equipment Co., Ltd. made a wonderful appearance at the two highly anticipated industry events, Qingdao International Rubber and Plastics Exhibition and Shanghai International Rubber Exhibition.

View More

The film roll cooling line is an automated device used to handle hot film in the production process of rubber products

View More

As 2026 begins, Qingdao Augu sends warm New Year wishes to all new and old customers!Thank you for your trust and companionship this past year—your support fuels our progress. In 2026, the tire industry is advancing toward smarter, greener development, brimming with fresh opportunities.We look forward to continuing our partnership: let’s explore tire machinery innovation and industry prospects together, aiming for mutual success. Wishing you thriving endeavors and all your wishes fulfilled in the new year!

View More

Qingdao Augu Automation Equipment Co., Ltd.’s spring turn up building machine is a practical must-have for rubber factories, ideal for 8–18 inch motorcycle outer tires. It features a 3-speed adjustable main shaft (35/70/120 rpm), 4-layer feeding for diverse processes, and segmented rolling (high pressure for tread, low pressure for sidewall) to ensure tight, uniform forming. With 13 years of rubber machinery expertise, we adopt reliable core components from Mitsubishi and AirTac. The equipment runs stably and supports customization per production line needs. We offer thorough pre-sales communication and quick after-sales response. Welcome to visit our factory, inspect equipment operation, and discuss cooperation!

View More

Concerned that the horizontal cord cutting machine can’t meet your production needs? Augu breaks the "fixed template" and adheres to the "one customer, one plan" customization principle! No matter your special technical parameter requirements or specific process standards, just share them with us. Our professional R&D team will tailor solutions—covering cutting precision, width adaptation, and automatic linkage—to perfectly match your production line. With years of rubber machinery R&D expertise, our equipment is precise and stable, ideal for various rubber products. Welcome to discuss your needs for exclusive equipment!

View More

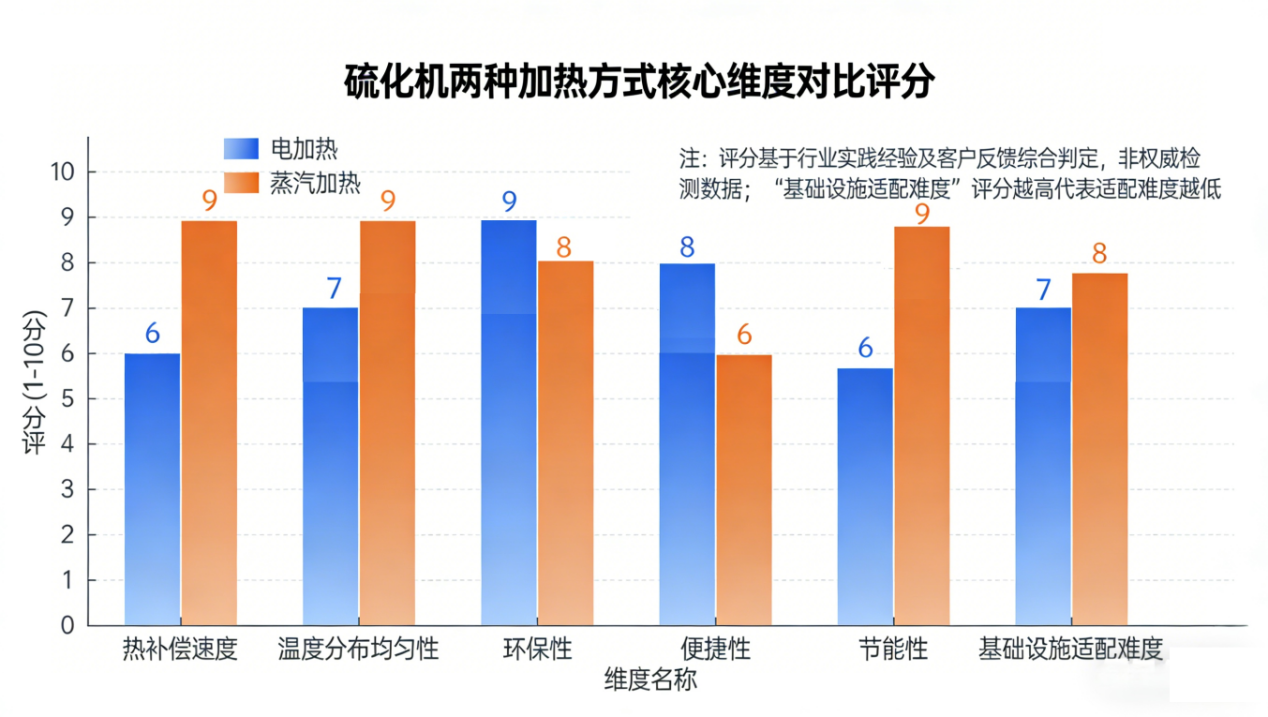

There is no absolute advantage or disadvantage between the electric heating and steam heating methods for vulcanizer hot plates. The core differences are reflected in the process response speed, infrastructure requirements and operational characteristics. If the factory focuses on environmental protection and convenience, has limited infrastructure investment and stable power supply, the electric heating method is more suitable; if the factory pursues heat compensation speed, temperature distribution uniformity and long-term energy-saving benefits, and has the conditions and capabilities for boiler construction, the steam heating method is more appropriate. It is recommended to comprehensively determine the optimal heating method based on the factory's actual construction plan, production scale and operational needs.

View MoreFor inquiries about rubber mixing process, tire building process, rubber equipment or price list, please leave your email to us and we will be in touch within 24 hours.